In the dynamic realm of modern industry, the term “digital transformation” isn’t just a fleeting trend; it’s a seismic shift that’s redefining the very essence of manufacturing. But what does this encompass, and why is it indispensable for businesses today?

Understanding Digital Transformation

Digital transformation in manufacturing entails harnessing cutting-edge technology to revolutionize traditional processes, empowering companies to operate with unprecedented intelligence, agility, and efficiency. Envision a factory where machines communicate seamlessly, production schedules adapt in real-time, and every facet of the supply chain is finely tuned for optimal performance. This is the essence of digital transformation.

Entering the World

Enter Manufacturing Execution Systems (MES) and Manufacturing Operations Management (MOM), the dynamic duo fueling the digital revolution in manufacturing. These technological marvels orchestrate production processes, fine-tuning operations, and injecting quality into every step. Real-time insights empower decision-makers, transforming factories into hubs of precision and productivity.

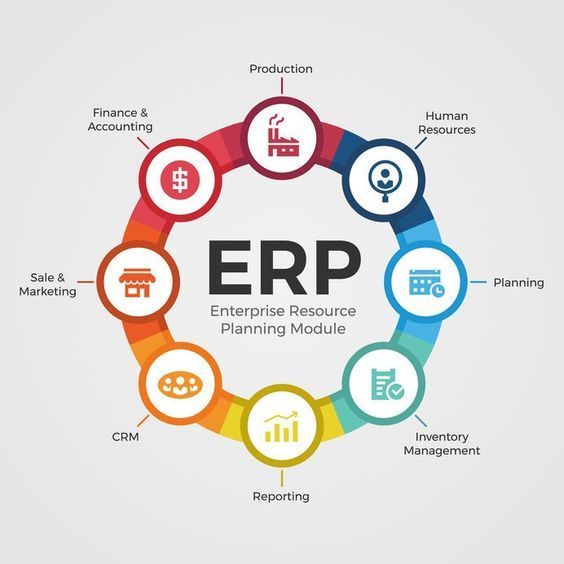

Now, let’s dive into the heart of digital prowess – Enterprise Resource Planning (ERP). Think of SAP, NetSuite, and Salesforce as digital maestros conducting a symphony of business processes. They harmonize disparate functions, streamline operations, and unveil a treasure trove of data insights. With ERP at the helm, businesses navigate the complex seas of competition with finesse and agility.

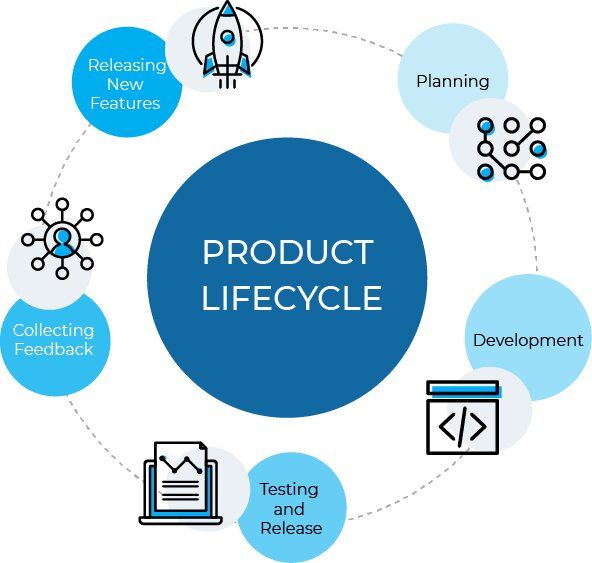

In the realm of innovation, Product Lifecycle Management (PLM) emerges as a catalyst igniting creativity and efficiency. PLM platforms nurture collaboration, expedite product development, and pave the way for groundbreaking inventions. This digital muse fuels the flames of innovation, ensuring that companies stay ahead in the race towards progress.

Supply Chain Management (SCM) emerges as the unsung hero of the manufacturing saga. It weaves a tapestry of efficiency, seamlessly connecting suppliers, manufacturers, and customers. SCM optimizes processes, slashes costs, and paints a portrait of streamlined operations, ensuring that products reach consumers in a timely and cost-effective manner.

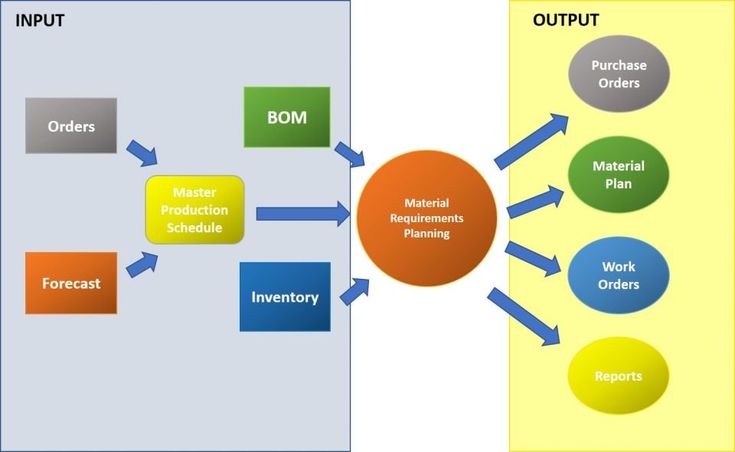

Material Requirements Planning (MRP) steps into the spotlight, orchestrating the ballet of materials with precision and finesse. By forecasting demand, managing inventory, and optimizing production schedules, MRP ensures a seamless symphony of resources, minimizing waste and maximizing efficiency.

In a world where manufacturing reigns supreme, digital transformation is the crown jewel. By embracing ERP integration for seamless operations, companies unlock the gates to efficiency, informed decision-making, and unparalleled business performance. The digital age heralds a new dawn, where innovation and technology converge to sculpt a future brimming with possibilities.

The Imperative for Change

Competitive Advantage: IDC’s research indicates that 35% of companies that embrace digital transformation gain a significant competitive edge in their respective markets.

Operational Efficiency: McKinsey’s findings reveal that digital transformation initiatives can yield a remarkable 20-30% increase in operational efficiency.

Customer Experience: PwC’s insights underscore that a staggering 73% of customers consider experience a decisive factor in their purchasing decisions, underscoring the critical importance of personalized and seamless interactions.

The Core Technologies Driving Transformation

MES/MOM (Manufacturing Execution Systems/Manufacturing Operations Management): These systems provide real-time visibility into production processes, facilitating informed decision-making. General Electric’s implementation of MES/MOM solutions resulted in a remarkable 50% reduction in cycle time.

ERP (Enterprise Resource Planning): By centralizing data and processes, ERP systems like NetSuite and SAP enhance collaboration and efficiency. According to Deloitte’s report, a staggering 87% of manufacturing executives believe that digital transformation offers a pivotal competitive advantage.

PLM (Product Lifecycle Management): PLM fosters innovation by streamlining collaboration and version control. Boeing achieved a commendable 30% reduction in development time and a remarkable 70% decrease in errors with the adoption of PLM software.

SCM (Supply Chain Management): By optimizing inventory and bolstering visibility, SCM ensures streamlined operations. Walmart, for instance, witnessed a notable 16% reduction in stock-outs following SCM implementation.

MRP (Material Requirements Planning): MRP systems balance inventory levels with production requirements, driving cost-efficiency. 3M realized an impressive 20% reduction in inventory levels and a commendable 15% enhancement in on-time delivery with MRP integration.

Industry Trends and Future Outlook

IoT Investment: The International Data Corporation predicts a staggering $450 billion spending on IoT in manufacturing by 2020, catalyzing advancements in automation and analytics.

Impact of Industry 4.0: McKinsey forecasts that Industry 4.0 technologies could generate an awe-inspiring $3.7 trillion in value by 2025, fundamentally transforming manufacturing processes.

The transition towards digital transformation in manufacturing isn’t merely a trend; it’s an imperative for survival and prosperity in today’s fiercely competitive landscape. By embracing MES/MOM, ERP, PLM, SCM, and MRP technologies, companies can unlock unprecedented levels of efficiency, agility, and innovation. The statistics unequivocally affirm this: the future of manufacturing is undeniably digital, and those who adeptly adapt will undoubtedly thrive in the ever-evolving market.